Avoid Costly HVAC Failures with Tube Testing

When it comes to HVAC systems, efficiency and reliability are non-negotiable. A crucial part of keeping your HVAC system running smoothly is the heat exchanger. Similar to looking after your lungs, which is important for your health, tube testing is essential for the proper functioning and efficiency of your HVAC system. In this blog, we will explore what Trane tube testing is, why it is important, and how it can benefit your HVAC system.

Tube-in-shell heat exchangers

In your HVAC equipment, heat exchangers enable the heat transfer from the cold side to the hot side. Tube-in shell heat exchangers contain several hundreds of copper tubes with advanced technology profile for the highest heat exchange efficiency. The tubes are all under mechanical stress and are subject to chemical corrosion.

Beware of deterioration - it’s important to detect any defects early

While your HVAC equipment may seem to be performing well, exchanger tube conditions may slowly be deteriorating, and a breakdown is just around the corner.

Damage to tubes may cause leaks into the rest of the equipment stopping the production of chilled water but also damaging compressor mechanism and heat exchanger internal elements, ultimately leading to major system breakdowns. And although maintaining good tube condition is critical to equipment performance, tubes may not be checked during standard maintenance calls.

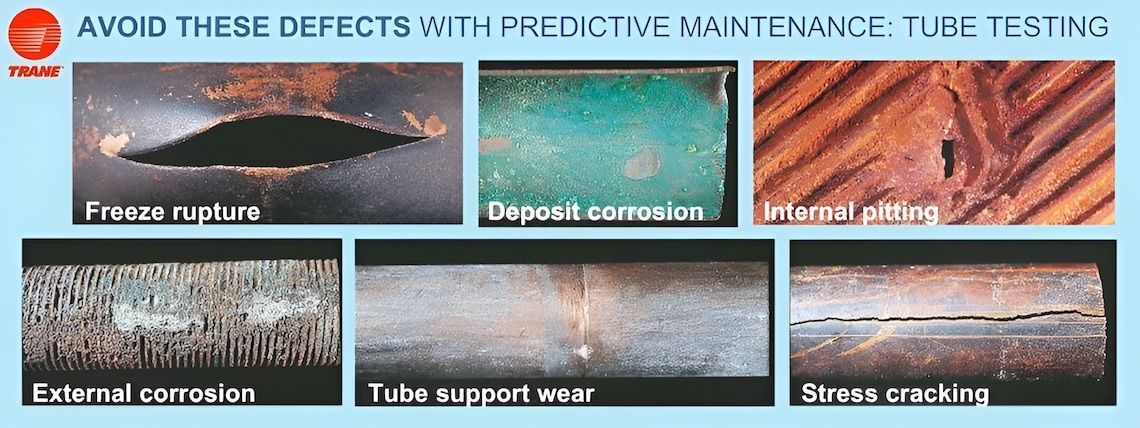

Chemical defects such as

- External corrosion caused by air intrusion

- Deposit corrosion caused by algae and slime due to inadequate water treatment.

- Internal pitting caused by abnormal presence of aggressive elements in water

Mechanical defects such as

- Freeze ruptures caused by low water flow in the evaporator

- Tube support wear caused by the tube/support contact. Although this phenomenon is quite rare, it must be quickly detected.

- Stress cracking which are longitudinal or intergranular cracks caused by high water flow

Benefits of Trane Tube Testing

Exchangers are relatively easy to maintain but can be very expensive to repair or replace. Maintaining heat exchangers in optimum condition will result in:

• Protecting 90% of your equipment (i.e. exchangers and compressors)

• Improved equipment operation and reliability

• Extended equipment life

• Reduced risks of costly breakdowns

• Reduced downtime.

The Eddy Current Tube Testing Process

Trane has over 30 years of tube testing experience and was the first HVAC manufacturer to apply the Eddy Current technique.

Equipped with the latest technological tools, Trane can detect, locate and record internal and external corrosion, deposits, wear or cracking before their consequences start to damage your installation. Trane specialists use an inspection probe inside each tube of the exchanger unit to detect the magnetic field that is generated by the eddy currents. The magnetic field being produced by these eddy currents is monitored with a micro-processor-based memory oscilloscope. If a defect such as a crack is detected in the tube, the magnetic field from the eddy currents will be disturbed from their normal circular shapes and a change in the signal will display on the screen. Eddy current tube analysis should be conducted as a part of predictive and curative maintenance program. It is the recommended scientific method to identify the root cause of a problem, and the extent of damage caused to the tubes.

In some cases, tube cleaning can be required prior to the Eddy Current procedure to remove deposits that could hinder the test.

The process generally requires 1-2 days of downtime.

What do you receive from Trane after an Eddy Current tube testing procedure?

• Analysis of signal on memory oscilloscope

• Defect recording on strip-chart

• Defect type identification

• Endoscopic inspection of detected faults

Report 1: Preliminary report produced on site.

Report 2: Full report within 1 week including a test summary, tube-by-tube results, tube-sheet defect analysis, graphic recordings, photographs of defective zones, and most importantly, Trane’s technical recommendations.

If your report shows that intervention is necessary, a Trane technical expert will propose practical actions to resolve the situation and will offer his assistance to restart your chiller.

We will suggest a routine based on system performance and service conditions. More demanding environments may require more frequent maintenance.

Conclusion

Trane tube testing is essential HVAC predictive maintenance that should not be overlooked. By investing in regular testing and maintenance, you can ensure the efficiency, reliability, and longevity of your HVAC system. Don't wait for a problem to arise. We are the experts you can rely on.

Schedule your Trane tube testing today

Contact Us

Connect with your local Trane expert

We will help you find the needed solution