Energy efficiency and cost savings are more critical than ever. Businesses are constantly seeking innovative solutions to optimize their operations. One solution not to overlook is the integration of heat recovery systems into HVAC units. Rooftops are available today with factory-mounted advanced heat recovery systems, offering a real opportunity to enhance energy savings and reduce operating costs with minimal impact on unit footprint and commissioning time.

When does Heat Recovery make sense?

Heat recovery systems are particularly beneficial in climates where there is a significant difference between outdoor and indoor air temperatures. During winter months, for example, the system can capture the heat from the exhaust air and use it to pre-condition the incoming cold air, reducing the load on the heating system.

What are the most effective heat recovery technologies available today for rooftops?

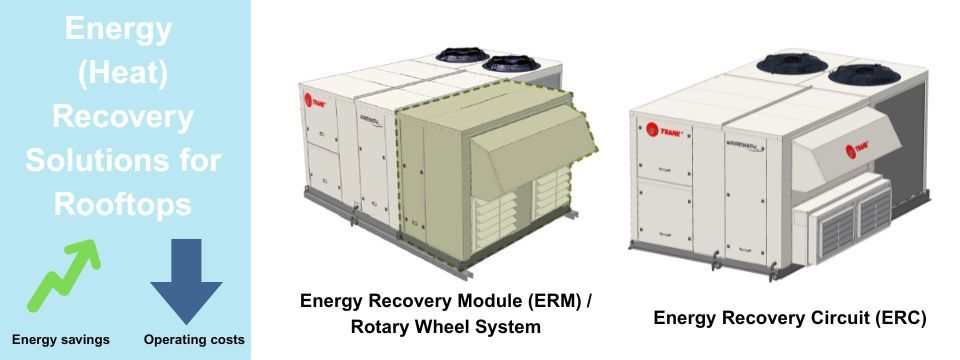

Two of the most popular and proven technologies are Energy Recovery Modules (ERM) and Energy Recovery Circuits (ERC).

What are Energy Recovery Modules (ERM)?

An Energy Recovery Module (ERM) is a rotary wheel system designed to transfer both sensible and latent heat from the exhaust air to the fresh air being introduced into the building. This process is facilitated by an enthalpy wheel, which is at the heart of the ERM. The enthalpy wheel captures and transfers heat, significantly reducing the energy required to condition the incoming air.

The overall capacity of a rooftop can be increased up to 50% in typical working conditions.

Key Benefits of the Energy Recovery Module:

1. Pre-Packaged Assembly: The ERM comes as a fully packaged assembly, which simplifies the installation process. This reduces total installation costs and time, making it a cost-effective solution for businesses.

2. No Need for Special Roof Curbs: The ERM is designed to manage exhaust air in applications with low to medium external static pressure without the need for special roof curbs. This further simplifies installation and reduces associated costs. Moreover, thanks to the exhaust fans, the pressure inside the building is properly managed.

3. Micro-Inverter Technology: In especially cold environments, the ERM is equipped with a micro-inverter that manages the rotation speed of the enthalpy wheel. This prevents ice formation on the wheel, ensuring continuous and efficient operation even in harsh winter conditions.

ERM is a solution appreciated in different climates, the wider the difference in temperature between indoor and outdoor, the higher the efficiency of the wheel.

What is an Energy Recovery Circuit (ERC)?

An Energy Recovery Circuit (ERC) is another innovative component designed to maximize energy efficiency. The ERC features a dedicated high-efficiency refrigeration circuit that uses exhaust air to pre-heat or pre-cool the fresh air introduced into the building. By recovering the heat in the exhaust air, the overall capacity of the rooftop can be increased by up to 25% in typical working conditions, without significantly impacting power consumption. As a result, the overall efficiency of the rooftop unit is increased considerably, especially at part load conditions.

Key Benefits of the Energy Recovery Circuit:

1. Fully Integrated Design: The ERC is integrated into the unit, having almost zero impact on the installation footprint. This ensures that the system remains compact and easy to install.

2. Standard Exhaust Module: An exhaust module is provided as standard and mounted directly under the fresh air damper. This avoids the need for additional equipment to manage the exhaust air for applications with low to medium static pressure requirements.

3. Superior Performance: Thanks to the additional refrigeration circuit and tighter control of the exhaust air, the Trane ERC system guarantees superior performance compared to alternative systems that utilize the outdoor coil.

ERC is a solution appreciated in Mediterranean climates, with warm summers where the recovery refrigerant circuit can operate at its best.

How much energy can we save? A case study.

Let’s consider a 22,000 m3/h rooftop unit, that has to operate with 30% fresh air to guarantee proper air renewal in a building.

If we consider the average climate conditions as defined in the EN14825:2022, the same unit with an ERM can save up to 30% primary energy (electricity) thanks to the energy recovered by the rotary wheel.

Conclusion

Integrating heat recovery systems into rooftops is a smart investment for businesses. By leveraging the benefits of heat recovery, businesses can see a quick return on investment, achieve significant energy savings and contribute to a more sustainable future.

See Trane's heat recovery solutions on rooftops

Read about ERM boosting savings in Portugal

Contact Us

Connect with your local Trane expert

We will help you find the needed solution