As businesses and industries strive to reduce operational costs and environmental impact, maintaining the efficiency of water-cooled HVAC units is critical.

Who's the culprit? Fouling!

Over time, water-cooled units, such as chillers, may suffer from fouling of their heat exchanger surfaces. Fouling occurs when impurities in the water, such as minerals, algae, and other debris, accumulate on the surfaces of the heat exchanger tubes. This buildup acts as an insulating layer, impeding heat transfer and causing the system to lose efficiency.

As efficiency declines, compressors are forced to operate at higher temperatures and pressures to achieve the desired cooling effect. This not only increases energy consumption but also leads to higher operating costs. In fact, just a 1°C increase in condenser temperature can result in a 2% increase in operating costs. Clearly, fouling is a significant issue that needs to be addressed to maintain optimal system performance.

One of the most effective ways to avoid fouling is through the implementation of an automatic tube cleaning system.

Automatic tube cleaning solutions

Let's look at the different automatic tube cleaning technologies available, how they work, and their benefits, so you can make an informed choice. Automatic tube cleaning systems offer a robust solution to the problem of fouling. By continuously cleaning the heat exchanger surfaces, these systems ensure that efficiency is maintained at peak levels and energy consumption is minimized. The systems operate without the need for periodic HVAC shutdowns, saving both time and money.

What are Effective Technologies?

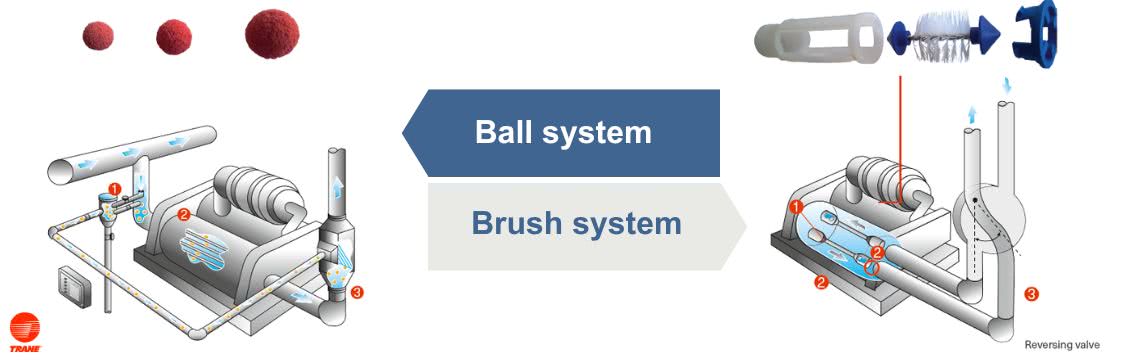

Two very efficient technologies available today for automatic tube cleaning are ball technology and brush technology. See figure and key below.

• Ball Technology

This method involves the use of sponge balls that are injected into the water flow. These balls travel through the tubes, scrubbing away any deposits and fouling. The balls are then collected and recirculated for continuous cleaning.

• Brush Technology

Brush technology uses brushes that are driven through the tubes by the water flow. The brushes remove any buildup on the tube surfaces, ensuring that they remain clean and efficient.

What are the Benefits of Automatic Tube Cleaning Systems?

Implementing an automatic tube cleaning system offers a multitude of benefits, making it a valuable investment for any facility with water-cooled units.

Short Pay-Back: Automatic tube system often have payback times of less than 2 years. Configurations with chillers operating in process applications show return of investment even much quicker. Trane can make customized evaluation of your specific site.

No Chiller Downtime: One of the most significant advantages of these systems is the elimination of costly and inconvenient downtime. Traditional tube cleaning methods, such as chemical cleaning, require periodic shutdowns of the HVAC system, disrupting operations and incurring additional costs. With continuous cleaning during chiller operation, downtime is no longer a concern.

Adaptable Solutions: Automatic tube cleaning systems are adaptable to all tube-in-shell heat exchangers. The systems are supplied fully programmed with settings for varied water quality, ensuring optimal performance regardless of the specific conditions of your facility.

Improved Operating Efficiency: The system ensures that your chiller operates at maximum efficiency. This leads to lower energy use and consequent cost reduction. With energy costs being a significant portion of operational expenses, the savings can be substantial.

Extended Chiller Life Cycle: When compressors operate beyond their design criteria due to fouling, it can lead to premature wear and tear. By eliminating condenser tube fouling, automatic tube cleaning systems help extend the life cycle of your chiller. This means fewer replacements and lower capital expenditures over time.

Low Maintenance Solution: The sponge balls and brushes used in automatic tube cleaning systems have a long service life and are the only consumables. This translates to low maintenance requirements and reduced operational hassle.

Reduced Water Treatment Costs: Water treatment is typically required to prevent scaling and fouling in HVAC systems. However, with automatic tube cleaning systems, water treatment is only necessary to prevent scaling of ancillary equipment. This can lead to cost savings of up to 50% on chemicals, further reducing operational expenses.

Zero Environmental Impact: These systems use no chemicals, creating no waste or pollution. This not only benefits the environment but also aligns with corporate sustainability goals.

Conclusion

By continuously cleaning the heat exchanger surfaces, these systems ensure peak performance, lower energy consumption, and extended equipment life.

Ball system (see figure below)

1 = Sponge balls are regularly injected at the exchanger inlet

2 = Balls are carried by the water flow through the condenser tubes, removing scale and fouling and keeping the tubes clean.

3 = Balls are trapped at the outlet and driven back to the inlet to start a new cleaning cycle.

Brush system (see figure below)

1 = Every condenser tube is fitted with baskets on each side, containing one brush.

2 = The brush is driven from one end of the tube to the other by the water flow. A reversing valve switches the flow direction to drive the brush back.

3 = The flow direction returns to normal at the end of the cycle.

Learn about Trane’s Automatic Tube Cleaning solutions

Contact Us

Connect with your local Trane expert

We will help you find the needed solution